Technologies

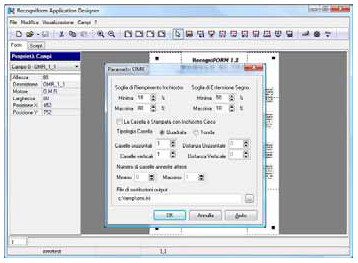

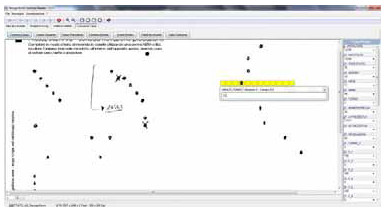

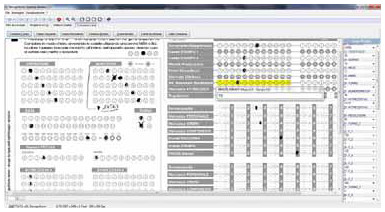

- OMR

- ICR

- OCR

- BCR

- BCR 2D

- OCR-A

- OCR-B

- MICR CMC7

- MICR E13B

- CHR

- FreeForm

- Form Identification

- PDF-A

- Image Enhancement

- TWAIN and ISIS Scanning

- Imaging

- Deskew

- Auto-Orientation

- Black Border Removal

- Despeckle

- Lines Removal

- Dynamic Thresholding

- Layout Analysis

- Quality Control

- Watermarking

- Redaction

- File Format Conversion

- Book Curvature Correction

- Keystone Correction